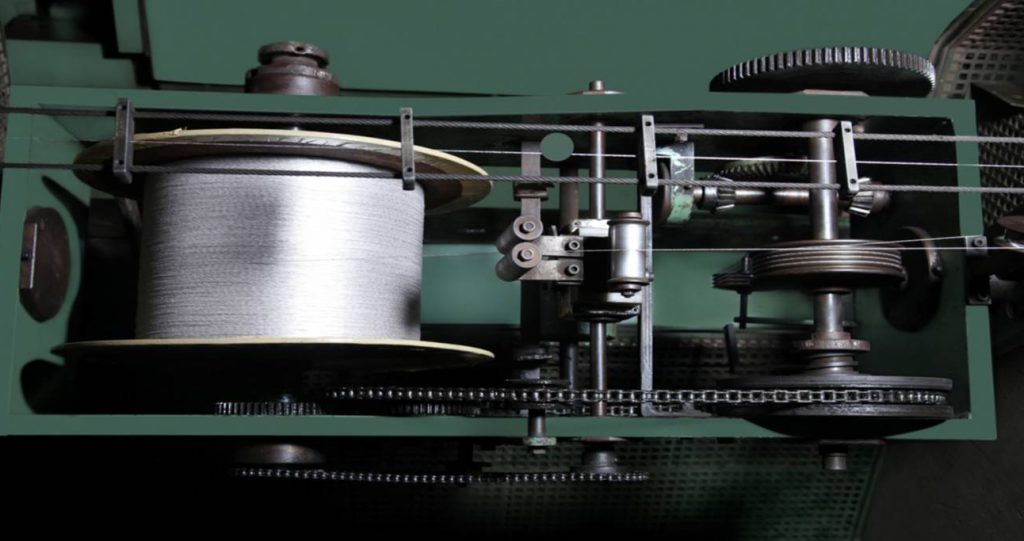

Copper rods in 8mm diameter will be drawn into finer diameters of upto 1.60 – 2.00mm, these copper wires will be electroplated with lead free tin. The tinned material will be drawn into finer gauges, diameters may range between 0.08mm – 0.200 mm. This drawing process is a multiple drawing process and the final drawing into the finer sizes will be done on the multi-line…the multi-line is a very modern machine, which has the unique capability to draw upto 14 wires in parallel. The fine gauges will be drawn in multiples of 7 usually. These multiple wires will be taken on the high speed double twist stranders called the ‘Lesmos’, these stranders are fully PLC controlled machines with speed, twists/inch , direction of twist all under monitor through the PLC. Multiples of 7 or 19 ends will be stranded to form the composite conductor.This conductor will be respooled through a sizing die and checked for electrical and physical parameters, this is the final product.